Technologies

Desto

Innovative cup packaging with cardboard sleeve

The innovative Desto cup combines the lightness and flexibility of plastic with the stability and aesthetics of cardboard. This combination not only improves the feel and appearance of the cup, but also offers additional functional benefits. The tear-off perforation makes it easier to open, while the viewing window in the carton allows the contents to be seen without having to open the cup. The stitch code on the base makes it easy to identify and trace the product. These features make the Desto cup an attractive solution for packaging requirements that emphasise both functionality and design.

Thermoforming

Efficient moulding for mass production

The thermoforming process at Volpini is characterised by the use of high-precision, computer-controlled thermoforming machines, which make it possible to form the heated films into complex shapes with fine details. This process is particularly efficient for mass production as it enables fast cycle times and high production rates. Volpini demonstrates its commitment to sustainability and resource efficiency by recycling the die-cut grid that is created when the cup moulds are cut out.

The Productionprocess with Volpini

Extrusion

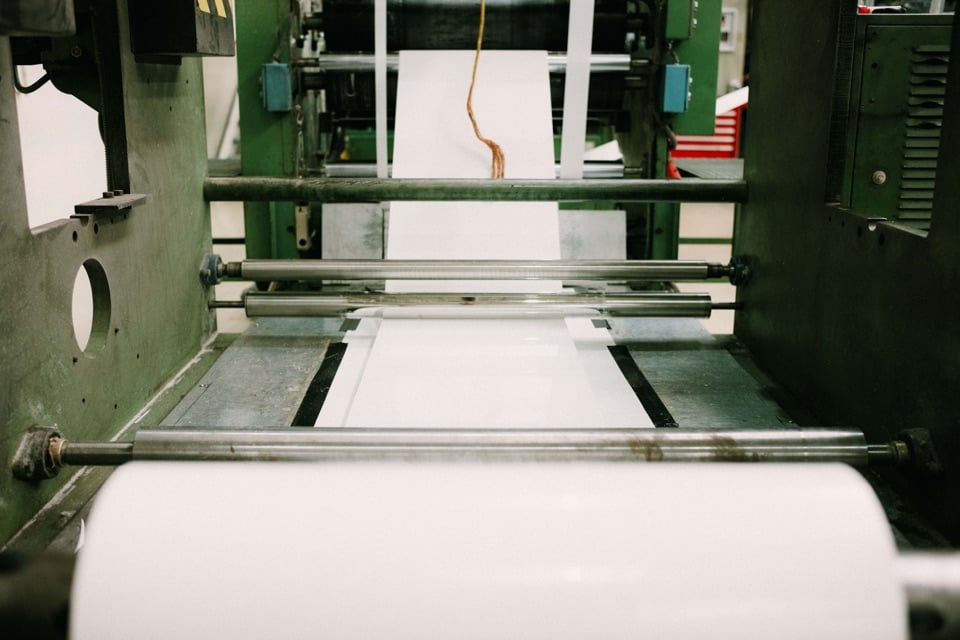

Precise moulding of plastic films

In the extrusion process, Volpini uses state-of-the-art equipment to first melt plastic granulate. The melt is then pressed through a die to form films or foil with precise thicknesses and widths. This process enables the production of films with different properties, such as transparency, flexibility and barrier properties, depending on the application of the end products. The technology also allows multi-layer films to be produced for improved functionality by combining different material types in a single pass. The precise temperature and pressure control ensures consistently high film quality.

Dry offset

Multi-colour printing for versatile designs

The dry offset process is an advanced printing technique used by Volpini for multicolour printing on plastic cups. This method makes it possible to produce detailed and vibrant images and text in up to nine colours. A key advantage of the dry offset is the fast drying of the printing inks, which enables immediate further processing of the printed products. This process is particularly suitable for materials such as polystyrene (PS) and polypropylene (PP), which gives Volpini the flexibility to respond to the specific requirements of its customers.

Der Unterschied zwischen direkt bedruckten und Desto-Bechern

Petra Feichter

Contact

Please contact us:

You can reach us by telephone on weekdays from 08:00 – 17:00, except Fridays 08:00 – 14:00